Rotary Coaters

Coating Tech

At SPE we provide the training in the Science and Art of pelleting and other coating techniques to customers to give each customer the ability to create within a very short time frame the most profitable operation producing high quality seed pellets and coated seeds.

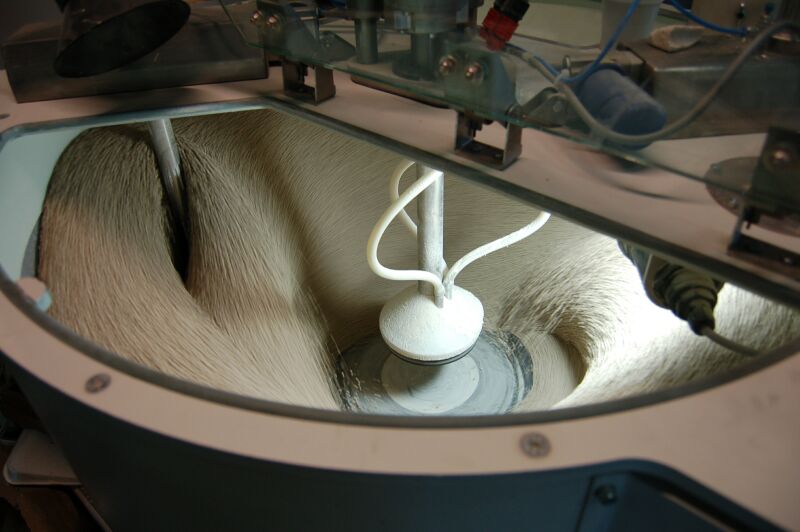

The coating chamber has been optimized for a smooth movement of the product, reducing the risk of broken pellets while optimizing the shape of the pellets. Running a good process with the right materials will keep the coating chamber clean, which is one of the most important aspect in producing high quality pellets.

Capacities of rotary coaters:

- RP1000 - 40 inches diameter coating chamber

Pelleting: pellet size 3.0-3.5 mm approximate 4 million pellets per batch

pellet size 2.0-2.5 mm approx. 6~8 million pellets per batch

Encrusting: max. 50~60 kg encrusted seed depending on density

Filmcoating: 6~50 kg seed depending on density and filling of the machine - RP800 - 30 inches diameter coating chamber:

Pelleting: pellet size 3.0-3.5 mm approximate 1.4 million pellets per batch

pellet size 2.0-2.5 mm approximate 3 million pellets per batch

Encrusting: max. 25~30 kg encrusted seed depending on density

Filmcoating: 4~25 kg seed depending on density and filling of the machine - RP600 - 24 inches diameter coating chamber:

Pelleting: pellet size 3.0-3.5 mm approximate 0.5~0.7 million pellets per batch

pellet size 2.0-2.5 mm approximate 1.0~1.5 million pellets per batch

Encrusting: max. 10~15 kg encrusted seed depending on density

Filmcoating: 2~15 kg seed depending on density and filling of the machine - RP350 - 14 inches diameter coating chamber:

Pelleting: pellet size 3.0-3.5 mm approximate 0.1~0.2 million pellets per batch

pellet size 2.0-2.5 mm approximate 0.2~0.4 million pellets per batch

Encrusting: max. 0.2~2 kg encrusted seed depending on density

Filmcoating: 0.1~1 kg seed depending on density and filling of the machine